Time between overhaul (abbreviated as TBO or TBOH) is the manufacturer’s recommended number of running hours or calendar time before an aircraft engine or other component requires overhaul.

On rotorcraft many components have recommended or mandatory TBOs, including main rotor blades, tail rotor blades and gearboxes.

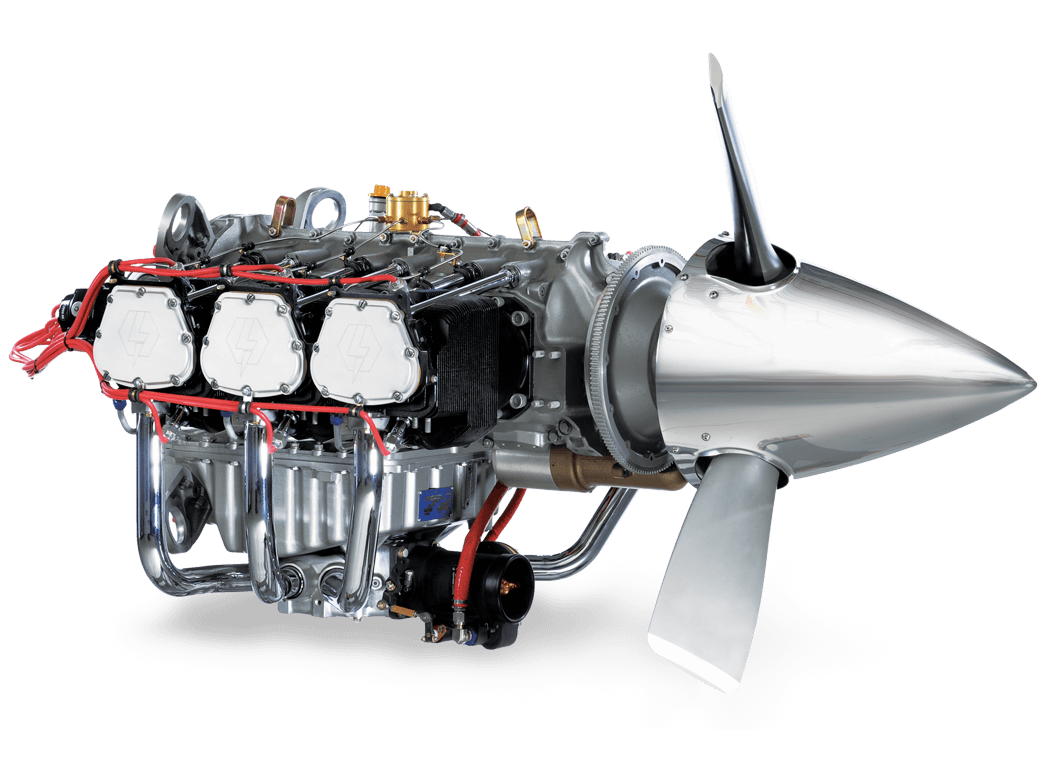

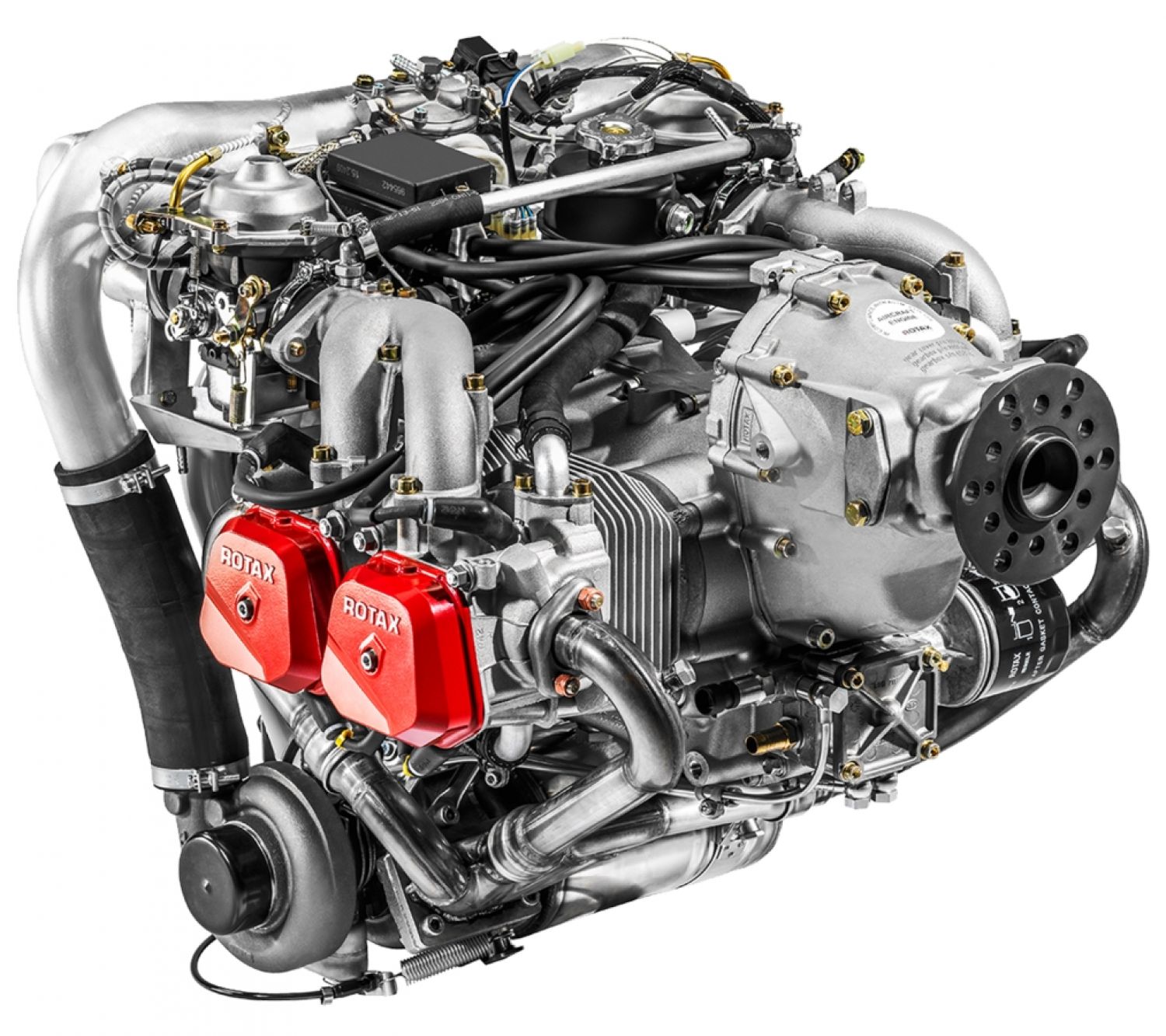

For engines the time between overhauls is generally a function of the complexity of the engine and how it is used. Piston-based engines are much more complex than turbine-powered engines, and generally have TBOs on the order of 1,200 to 2,000 hours of running time. They tend toward the lower number if they are new designs, or include boosting options like a turbocharger. In comparison, jet engines and turboprops often have TBOs on the order of 3,000 to 5,000 hours.

Since overhauling needs the engine to be taken apart, it is typically expensive. The value of a used engine decreases if it is close to needing an overhaul, so used engines (and aircraft) typically list their time since overhaul or TSOH.

The TBO is a time ‘recommended’ by the manufacturer and, depending upon what rules the aircraft operates under, overhauling the engine at this time is not necessarily mandatory. For aircraft used non-commercially overhauls are not mandatory, but highly recommended. Likewise, overhaul at the recommended TBO does not guarantee that the engine will last that long.